Problem

Relying on manually capturing and inputting production data from the floor creates an inaccurate look into your true utilization.

As a manufacturing shop, increasing profitability is key to your success. However, achieving that goal can be difficult when you don’t know how to improve overall utilization.

At Bearex, we understand the frustration that comes when you lack real-time information to make informed decisions and believe that you and your team should have access to machine data in order to make an immediate impact.

Relying on manually capturing and inputting production data from the floor creates an inaccurate look into your true utilization.

Connecting directly to the source, your machines, gives you an unbiased view into your true inefficiencies.

Factors of utilization are delivered to all levels of your operations, so you can run a more profitable shop.

Profitability dashboard for your manufacturing operations.

With intuitive dashboards, insightful analytics, and powerful reporting capabilities, you can keep real-time pulse on your operations and gain actionable insights to drive costs down and profits up!

Capture accurate data reports for machine capacity in order to quote RFP’s appropriately and quickly.

Understand downtime reasons in order optimize maintenance teams and keep machines running optimally.

Improve cycle times, setup times, and create more efficient tool changes.

Machine data is delivered in a way to provide true action.

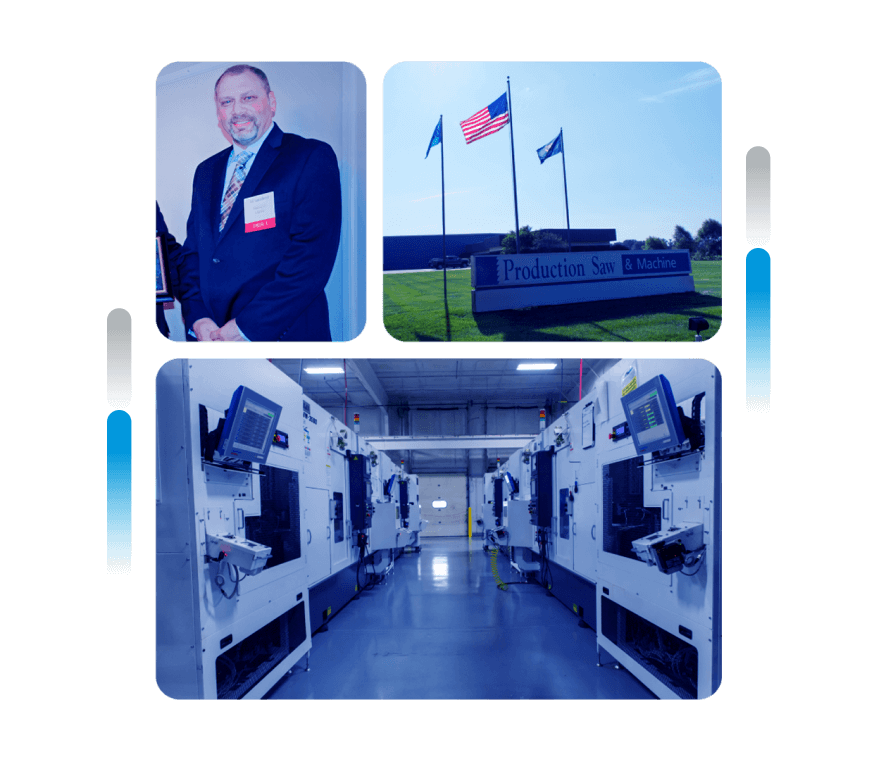

Jeff V.

President, Production Saw & Machine Co

Machine data delivered in a way to provide true action.

Bearex works hand and hand with you to create a plan for implementation.

Our pricing and pilot program is specifically designed to help small to mid-size manufacturers.

Our platform is easy to use so all members of your operation can begin use immediately.

We start by connecting directly to the source - Your machines. Whether they are legacy or brand new, we offer options in order to gain the insight needed to deliver results.

We combine information from your machines on parts produced with quality and scrap live from your operators.

We then deliver a simplistic platform that provides a live view into your machine's current performance and OEE.

The best way to define our culture is through our core values. Every relationship from employees, customers, to vendors we filter and uphold these values as our guiding light.